Titanium Alloy Aheet Plate

TC2 Titanium Alloy Aheet Plate,An stannum in Titanium cum aliis elementis additis.Duo genera crystallorum homogenarum in titanio sunt: α titanium densum hexagonum est infra 882℃, et β titanium cum centro corporis cubo est supra 882℃.

Requisita technica:

1. Compositio chemica bracteae titanii et titanii mixturae praescriptis GB/T 3620 observabit.

2. In casu restitutionis licita declinatio compositionis chemicae obtemperabit praescriptis GB/T 3620 .

a.licita declinatio crassitudinis bracteae servari debet praescripta Tabulae 1 .

b.licita declinatio bracteae latitudinis et longitudinis observare debet praescriptis Tabulae II.

c.anguli vero laminae in angulos rectos, quantum fieri potest, abscindi debent.schedae longitudinis et latitudinis excessus non excedunt

TC2 Titanium Alloy Aheet Plate, Productio Specification

T 0.5-1.0mm W1000mm L 2000-3500mm

T 1.0-5.0mm W1000-1500mm L 2000-3500mm

T 5.0- 30mm W1000-2500mm L 3000-6000mm

T 30- 80mm W1000mm L 2000mm

TC2 Titanium Alloy Aheet Plate, Production Status

Hot working state (R) Cold working state (Y) Annealing state (M)

TC2 Titanium Alloy Aheet Plate, Reference Standard

1: GB 228 Metal distrahens test methodum

2: GB/T 3620.1 Titanium et titanium mixturae gradus et compositionis chemicae

3: GB/T3620.2 Titanium et Titanium stannum processit productorum chemicorum compositio et compositio licita declinatio

4: GB 4698 Methodus superficiei maris chemicae analyseos titanii, titanii et ferroalloys

TC2 Titanium Alloy Aheet Plate, The Technical Requirements

1: Compositio chemica bracteae titanii et titanii mixturae praescripta GB/T 3620,1.In casu restitutionis licita declinatio compositionis chemicae obtemperabit praescriptis GB/T 3620,2.

2 : Licita declinatio bracteae crassitiei servari debet praescripta Tabulae 1 .

3: Licita declinatio tabule latitudinis et longitudinis parere debet praescriptis Tabulae II.

4: laminae angulos in angulos rectos, quantum fieri potest, secari oportet.schedae longitudinis et latitudinis excessus non excedunt

Alloying

TC2 Titanium Alloy Aheet Plate,An stannum in Titanium cum aliis elementis additis.Duo genera crystallorum homogenarum in titanio sunt: α titanium densum hexagonum est infra 882℃, et β titanium cum centro corporis cubo est supra 882℃.

(1) Permixtio elementorum dividi potest in tria genera secundum effectum ad tempus temperatus transitus;

α - stabilia elementa, sicut aluminium, carbonem, oxygenium et nitrogenium, stabilire α phase et augere Phase transitum temperatum.Aluminium est elementum principale offensionis titanii offensionis, quod effectum habet manifestam vim mixturae in cella temperie et caliditate augendam, reducendo gravitatem specificam et modulum elasticum augendo.

(2) β elementa stabilia in duo genera dividi possunt: isocrystallina et eutectoida.Products e Titanium stannum

Priora molybdenum, niobium, vanadium, et sic porro;Haec habet chromium, manganesum, cuprum, ferrum, pii et cetera.

(3) Elementa quae minimum momenti ad tempus temperatura transeunt, elementa sunt neutra, ut zirconium et stannum.

Oxygeni, nitrogenium, carbonis et hydrogenii sordes praecipuae sunt in admixtionibus titanii.Solubilitas oxygenii et nitrogenis in α phase maior est, quae notabile effectum in stannum titanium corroborat, sed plasticitatem decrescit.Contentum oxygenii et nitrogenium in titanio plerumque infra 0.15 ~ 0.2% et 0.04 ~ 0.05%, respective.Hydrogenium parum solubilitatem in α periodo habet, et nimium hydrogenii admixtiones in Titanio dissolutum hydrides facit, quae fragilem mixturae faciunt.Hydrogenium contentum in stannum titanium infra 0.015% contineri solet.dissolutio hydrogenii in titanio convertitur et per inane furnum tolli potest.

Compositio chemica

| Gradus | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.014 | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr2 | 0.03 | 0.08 | 0.014 | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr3 | 0.05 | 0.08 | 0.014 | 0.3 | 0.35 | / | / | / | / | / | Bal |

| Gr4 | 0.05 | 0.08 | 0.014 | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr5 | 0.05 | 0.08 | 0.014 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal |

| Gr7 | 0.03 | 0.08 | 0.014 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal |

| Gr9 | 0.03 | 0.08 | 0.014 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal |

| Gr12 | 0.03 | 0.08 | 0.014 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | Bal |

Distrahentes fortitudo

| Gradus | Prolongatio(%) | Fortitudo distrahentes (Min) | Fortitudo cede (Min) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |

Titanium And Alloy Products

| Product nomen | Specifications |

| Titanium Rod & Bar & Ingots | 3mm ~ 1020mm, maximum pondus est usque ad 12t |

| Titanium Slab | (80~400)mm×(~MD)mm×(~2600)mm |

| Titanium Forgings | Pondus per piece≤2000kg |

| Titanium Hot-rolled plates | (4~100)mm×(800~2600)mm×(2000~12000)mm |

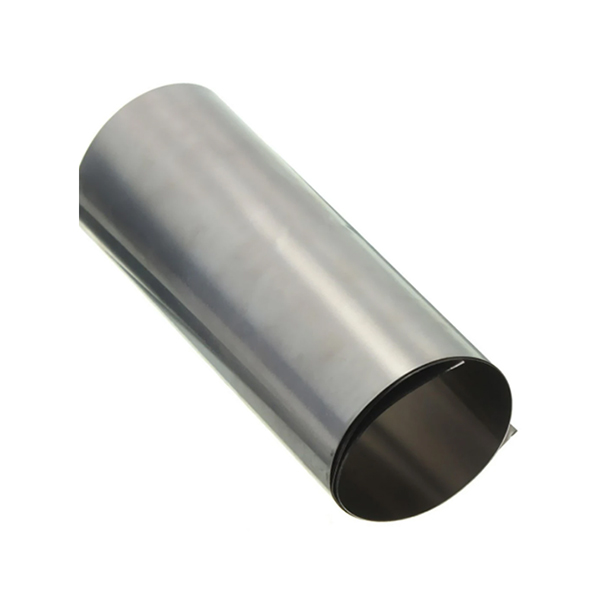

| Titanium Frigidi-volutus Sheet | (0.01~4.0)mm×(800~1560)mm×(~6000) mm |

| Titanium Foil / Strips | (0.01~2.0)mm×(800~1560)mm×L |

| Titanium Tubes / Pipes | (3~114)mm×(0.2~5)mm (~15000) mm |

| Signa | GB,GJB,ASTM,AMS,BS,DIN,DMS,JIS, ГОСт |

| Titanium Grade |

|

Productum Propono