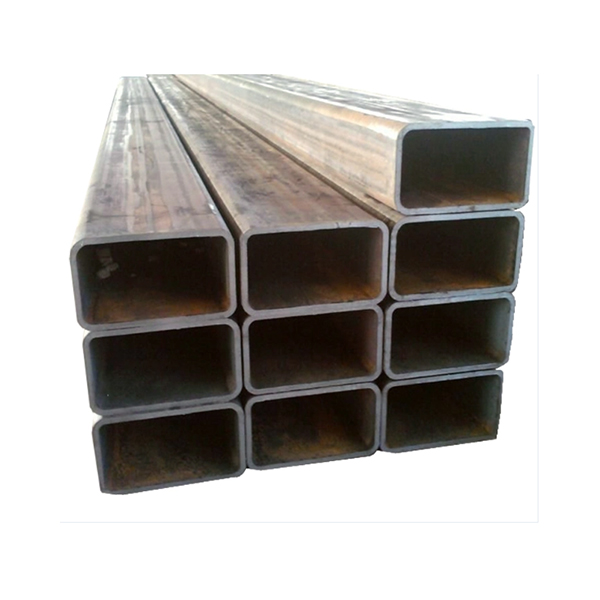

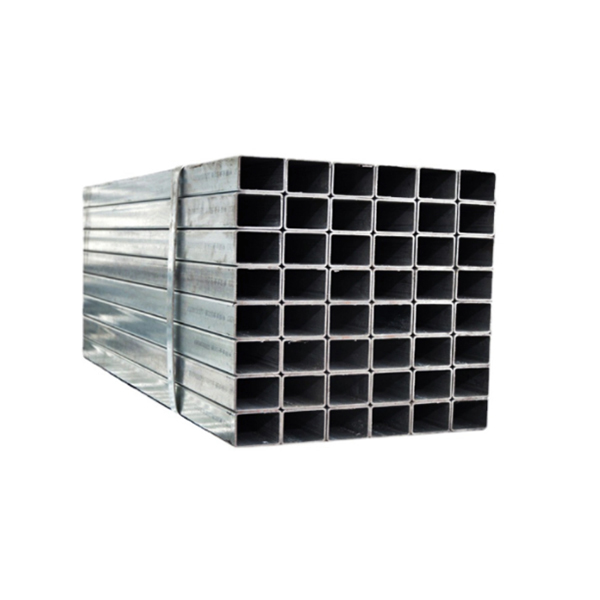

A513 tubus ferreus quadratus pro liquore onerariis

A513 Steel Square Tubing, murus creber quadratus tibia ferrea, tibia magna diameter quadratus ferreus, tibia ferrea inconsutilis quadrata, humilis fistula quadrata ferro mixtura, 135*135*10 quadratum chalybeis, turris gruis quadratum ferreum tibia, Q345B stannum quadratum ferreum fistula humilis, XX # seamless quadratum ferro pipe

A513 Steel Square Tubing, Ut nomen indicio est, figura quadrata est tubi, multa genera materiarum corpus tubi quadrati formare possunt, medium in quo utendum, ubi utendum, maxime tubi quadrati ad fistulam ferream. maior pars, plerumque tubus quadratus structuralis, tubus quadratus ornatus, tubus quadratus et sic porro.

A513 Steel Square Tubing, Nomen tubo quadrato, quod est tubus aequalis longitudinis.Fit ex ferro habena post processui et volubilem.Fuse, habena in tubo rotundo inpedita, librata, emensa et conflata, quae in tubo quadrato volvitur et in longitudinem debitam secetur.Plerumque L haeret per sarcinam.

A513 Steel Square Tubing, Sunt inconsutiles et firma puncta, inconsutilem quadratum tubus est tubus inconsutilem extrusionem fingens.Fistula ferrea quadratus, crassus tibia murus quadratus, tibia magna diameter quadratus ferreus, fistula quadrata ferrea inconsutilis, fistula humilis mixtura chalybea quadratus, fistulae ferreae 135*135*10 quadratum chalybe, turris gruis quadratum ferreum tibia, Q345B humilis mixtura quadratum chalybe fistula, 20 # Seamless quadratum ferro pipe

1. Exponentialis perficiendi analysis de tubulis quadratis - MOLLITIA

Plasticitas pertinet ad facultatem materiae metallicae producendi deformatio plastica (deformatio permanentis) sine damno sub onere.

2. Analysis indices euismod tubi quadrati - duritiei

Duritia est coniectura quam dura vel mollis materia sit metallica.In praesenti methodus communissima adhibita ad determinandam duritiem in productione est methodus indenter duritiem, quae uti est figura quadam geometrica capitis indenteri sub onere in superficie probatae materiae metallicae, secundum gradum probatae materiae. indentam suam duri- tiam determinare.

Communiter methodi adhibendae sunt Brinell durities (HB), Rockwell durities (HRA, HRB, HRC) et Vickers durities (HV) et alii modi.

3. euismod indicem analysin tubi quadrati - fatigationis

Fortitudo, plasticitas et durities supra disputata sunt indicibus proprietatum mechanicarum metallorum sub oneratione stabili.Complures partes machinae sub oneribus cyclicis operatae sunt, et labor sub his condicionibus accidere potest.

4. euismod indicem analysis fistulae quadratae - spissitudo ictum

Onus agens in partibus in magna celeritate impulsum onus appellatur, et facultas metalli resistendi damnum sub ictum oneris durities impulsum appellatur.

5. Fistula quadratus effectus index analysis - vis ferrea quadratus, murus quadratus tibia ferrea, magnus diameter quadratus chalybeus, fistula quadrata ferrea inconsutilem, fistulam ferream stannum humilis, 135*135*10 quadratum chalybeis, turris gruis quadratum ferreum tibia ;

Fortitudo est facultas materiae metallicae resistendi defectionis (nimis plasticae deformationis vel fracturae) sub static onerantibus.Ob modum onerationis in forma extensi, compressionis, flexionis, tonsurae, sic etiam vis dividitur in vires distrahentes, vires compressivas, inflectens vires, tondendas vires, et sic porro.Saepe connexio quaedam est inter varias vires, et distrahens robur plerumque adhibetur sicut monstratorem vi fundamentalis.

Magnitudo

| Magnitudo byInch (diameter) | Crassitudo | Magnitudines byMM (diameter) | Crassitudo |

| digitis | digitis | mm | mm |

| 1/2" x 1/2" | 0.093" | 16mm×16mm | 0.4mm~1.5mm |

| 3/4" x 3/4" | 0.049" | 18mm×18mm | 0.4mm~1.5mm |

| 0.093" | 20mm×20mm | 0.4mm~3mm | |

| 0.093" | 22mm×22mm | 0.4mm~3mm | |

| 0.120" | 25mm×25mm | 0.6mm~3mm | |

| 1" x 1" | 0.049" | 30mm×30mm | 0.6mm~4mm |

| 0.093" | 32mm×32mm | 0.6mm~4mm | |

| 0.093" | 34mm×34mm | 1mm~2mm | |

| 0.093" | 35mm×35mm | 1mm~4mm | |

| 0.093" | 38mm×38mm | 1mm~4mm | |

| 0.093" | 40mm×40mm | 1mm~4.5mm | |

| 0.109" | 44mm×44mm | 1mm~4.5mm | |

| 0.120" | 45mm×45mm | 1mm~5mm | |

| 1 1/8" x 1 1/8" | 0.035" | 50mm×50mm | 1mm~5mm |

| 0.049" | 52mm×52mm | 1mm~5mm | |

| 0.093" | 60mm×60mm | 1mm~5mm | |

| 0.109" | 70mm×70mm | 2mm~6mm | |

| 0.120" | 75mm×75mm | 2mm~6mm | |

| 1 1/4" x 1 1/4" | 0.049" | 76mm×76mm | 2mm~6mm |

| 0.093" | 80mm×80mm | 2mm~8mm | |

| 0.093" | 85mm×85mm | 2mm~8mm | |

| 0.093" | 90mm×90mm | 2mm~8mm | |

| 0.109" | 95mm×95mm | 2mm~8mm | |

| 0.120" | 100mm×100mm | 2mm~8mm | |

| 0.135" | 120mm×120mm | 4mm~8mm | |

| 0.149" | 125mm×125mm | 4mm~8mm | |

| 0.188" | 130mm×130mm | 4mm~8mm | |

| 1 1/2" x 1 1/2" | 0.049" | 140mm×140mm | 6mm~10mm |

| 0.093" | 150mm×150mm | 6mm~10mm | |

| 0.093" | 160mm×160mm | 6mm~10mm | |

| 0.093" | 180mm×180mm | 6mm~12mm | |

| 0.109" | 200mm×200mm | 6mm~30mm | |

| 0.120" | 220mm×220mm | 6mm~30mm | |

| 0.140" | 250mm×250mm | 6mm~30mm | |

| 0.188" | 270mm×270mm | 6mm~30mm | |

| 0.250" | 280mm×280mm | 6mm~30mm | |

| 1 3/4" x 1 3/4" | 0.093" | 300mm×300mm | 8mm~30mm |

| 0.093" | 320mm×320mm | 8mm~30mm | |

| 0.093" | 350mm×350mm | 8mm~30mm | |

| 0.109" | 380mm×380mm | 8mm~30mm | |

| 0.120" | 400mm×400mm | 8mm~30mm | |

| 0.188" | 420mm×420mm | 10mm~30mm | |

| 2" x 2" | 0.049" | 450mm×450mm | 10mm~30mm |

| 0.093" | 480mm×480mm | 10mm~30mm | |

| 0.093" | 500mm×500mm | 10mm~30mm | |

| 0.109" | 550mm×550mm | 10mm~40mm | |

| 0.120" | 600mm×600mm | 10mm~40mm | |

| 0.145" | 700mm×700mm | 10mm~40mm | |

| 0.165" | 800mm×800mm | 10mm~50mm | |

| 0.188" | 900mm×900mm | 10mm~50mm | |

| 0.250" | 1000mm×1000mm | 10mm~50mm | |

| 0.312" | |||

| 2 1/4" x 2 1/4" | 0.188" | ||

| 0.250" | |||

| 2 1/2" x 2 1/2" | 0.093" | ||

| 0.109" | |||

| 0.120" | |||

| 0.188" | |||

| 0.250" | |||

| 0.312" |

| 3" x 3" | 0.093" |

| 0.120" | |

| 0.188" | |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 3 1/2" x 3 1/2" | 0.120" |

| 0.188" | |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 4" x 4" | 0.093" |

| 0.120" | |

| 0.149" | |

| 0.188" | |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" |

| 4 1/2" x 4 1/2" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 5" x 5" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 6" x 6" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 7" x 7" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" |

| 8" x 8" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 9" x 9" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 10" x 10" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 12" x 12" | 0.250" |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 14" x 14" | 0.312" |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 16" x 16" | 0.312" |

| 0.375" | |

| 0.500" | |

| 0.625" |

De compositione chemica Material

| Gradus | elementum | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0.05%-0.23% | 0.3%-0.6% | 0.04% | 0.04% |

| Acc.to EN10027/1 | Acc.to EN10027/2 | C% max (Norminal WT(mm) | Si% max | Mn% max | P% max | S% max | N% max | |

| et IC 10 | ≤ 40 | |||||||

| S235JRH | 1.0039 | 0.17 | 0.20 | - | 1.40 | 0.041 | 0.041 | 0.009 |

| S275JOH | 1.0149 | 0.20 | 0.22 | - | 1.50 | 0.041 | 0.041 | 0.009 |

| S275J2H | 1.0138 | 0.20 | 0.22 | - | 1.50 | 0.035 | 0.035 | - |

| S355JOH | 1.0547 | 0.22 | 0.22 | 0.55 | 1.60 | 0.041 | 0.041 | 0.009 |

| S355J2H | 1.0576 | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | - |

Mechanica Materia

| Gradus | Cedat imperium | Distrahentes fortitudo | Prolongatio |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| Norm | Cedat imperium | Distrahentes fortitudo | Min.elogation | Min.percent possessiones | ||||||||

| Acc.to EN10027/1and IC 10 | Acc.to EN10027/2 | Normalis WTmm | Normalis WTmm | Longit. | Crucis | Test temperatus°C | Mediocris valorem min.impact | |||||

| ≤16 | >6 | >40 | <3 | ≤3≤65 | Normalis WTmm | |||||||

| ≤65 | ≤65 | ≤40 | >40 | >40 | ≤65 | |||||||

| ≤65 | ≤40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355JOH | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

Equivalent Specifications

| EN 10210-1 | NF A 49501 NF A 35501 | DIN 17100 DIN 17123/4/5 | BS 4360 | UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | - | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43 C | Fe 430 C |

| S275J2H | E 28-4 | St 44.3 N | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50 C | Fe 510 C |

| S355J2H | E 36-4 | St 52.3 N | 50 D | Fe 510 D |

| S275NH | - | St E 285 N | - | - |

| S275NLH | - | TSt E 285 N | 43 EE | - |

| S355NH | E 355 R | St E 355 N | - | - |

| S355NLH | - | TSt E 355 N | 50 EE | - |

| S460NH | E 460 R | St E 460 N | - | - |

| S460NLH | - | TSt E 460 N | 55 EE | - |

- littera littera "S" significat "FERRUM STRUCTURAL APPLICATIONS"

— altera figure means the minim.cede valorem pro muro requiritur crassitudo ≤16 mm

- "J2" significat impulsum test valorem -20° C min.27 joule

- littera littera "H" significat " SECTIO CAVA".

Productum Propono